LED防爆灯具生产厂家工艺要求,20W,30W,40W,50W,60W,70W,80W,90W,100WLED防爆灯生产要求,防爆灯具生产要求

LED防爆灯具生产厂家工艺要求

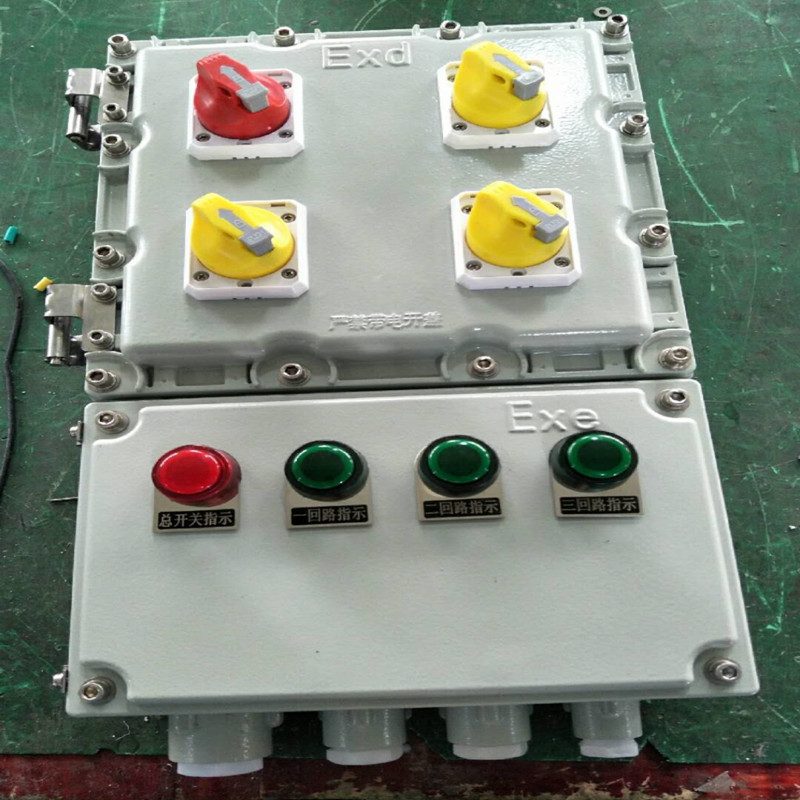

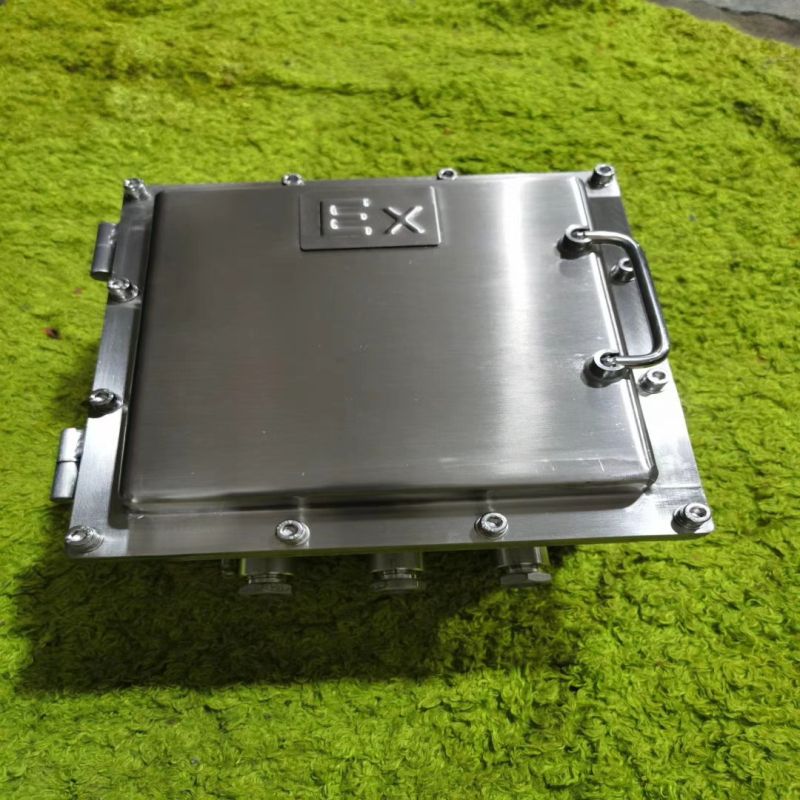

对于隔爆型灯具,隔爆外壳是这类隔爆型防爆电气设备的关键部件,所以隔爆外壳必须符合一般要求和隔爆性能的特殊要求。

1.一般要求

隔爆型灯具是一种特殊的灯具,防爆泛光灯必须符合普通灯具的通用要求。

1.1 灯具的外壳造型力求美观大方,结构紧凑可靠,轻便且工艺性要好。

1.2 要求有足够的容积用来放置灯座、灯泡、反射器、接线柱等电气元件和灯具配件,同时要考虑布局的合理性,便于安装、更换光源等使用和维修。

1.3 要有一定表面积的透明部分,以使灯具内部光源的光通量通过反射部件有效地投射出来。

1.4 要综合考虑散热、防尘、防水和防腐等措施,在结构上给予充分的保证。

1.5 在适当的位置,合理地布置内外接地,并有相应的永久性接地标志。

2.特殊要求

隔爆外壳国家防爆标准要求能承受内部爆炸性气体混合物的爆炸压力,并阻止内部的爆炸火焰向外壳周围爆炸性混合物传播;防爆泛光灯要满足这—性能,就必须具体考虑如下特殊要求:

2.1 耐爆性能。要求灯具外壳有足够的强度和刚度来承受灯具内腔可能引起的爆炸压力,因此要选择适当的材质和壁厚,组成*佳的立体几何形状分布,这种腔体结构, 既要美观大方,又要尽可能地避免形体变化过大所造成的应力不均,以便确保*终能够通过GB3836.2规定的动态强度试验。

2.2 隔爆功能。灯具的隔爆外壳在设计时就必须严格按照GB3836.2的规定选用适当的隔爆接合面结构参数、引入装置的方式,透明件与灯体部件的密封结构形 式、隔爆接合面的粗糙度,隔爆螺纹的精度等,以便有效地阻止内部爆炸火焰向外壳周围爆炸性混合物传播,*终通过GB3836.2规定的隔爆性能试验。

2.3 灯具的隔爆外壳,多数是由2个或多个连通空腔组成,往往很容易产生压力重叠现象,一般来说,防爆泛光灯这将会造成爆炸压力异常急剧上升而超过预计的*大压 力。为此应尽量增大联通孔面积,使外壳内部的形状能消除压力重叠现象。如果实际不能消除压力重叠现象,则应在腔与腔之间采取隔爆措施,消除压力重叠。

2.4 对于ⅡC的隔爆型灯具,GB3836.2严格规定不应采用爆炸时隔爆间隙趋向增大的平面隔爆接合面,为此,目前我国的隔爆型ⅡC防爆灯具大多数采用隔爆螺纹的结构形式,以便灯具更换光源或维修时灯具腔体能顺利开启。

LED防爆灯具:LED防爆灯具生产厂家工艺要求

For critical components flameproof lighting, flameproof enclosure is explosion-proof electrical equipment such , it is flameproof enclosure must meet the general requirements and the special requirements of explosion-proof performance .

1 . General requirements

Flameproof lighting is a special lighting, explosion-proof floodlight must meet the general requirements for ordinary lamps .

1.1 lamp shell shape seeks nice , compact structure, reliable, lightweight and better manufacturability .

1.2 requires sufficient volume to place the lamp, bulbs, reflectors , terminals and other electrical components and lighting accessories, taking into account the reasonableness of the layout , ease of installation, use and maintenance , such as replacing the light source .

1.3 have a transparent portion of the surface area , so that the light flux reflected by the light source inside the lamp member projecting out effectively .

1.4 takes into consideration the heat, dust, water and corrosion and other measures to give sufficient guarantees on the structure.

1.5 in place , reasonable layout inside and outside the ground , and a corresponding permanent ground sign.

2 . Special requirements

Explosion -proof enclosure national standards to withstand an internal explosion of an explosive gas mixture pressure and prevent internal explosion of an explosive mixture of flame spread to surrounding housing ; proof floodlight to meet this - performance , it must specifically consider the following specific requirements:

2.1 explosion -resistant properties. Lamp housing requires sufficient strength and rigidity to withstand the lamp lumen pressure may cause an explosion , so to select the appropriate material and wall thickness , composed of the best three-dimensional geometry of the distribution of this cavity structure , both nice, but also as far as possible to avoid overstressing the big physical changes caused by uneven dynamic strength testing to ensure the final through GB3836.2 regulations.

2.2 Explosion-proof function. Lamps designed flameproof enclosure must be strict selection of appropriate structural parameters in accordance with the provisions of flameproof joints GB3836.2 , the introduction of the device the way , in the form of sealed structure transparent parts and lamp body parts , flameproof joints roughness precision threaded explosion , in order to effectively prevent internal explosion of an explosive mixture of flame propagation around the housing , the final proof performance test prescribed by GB3836.2 .

2.3 lamps flameproof enclosure , the majority is composed of two or more communicating cavities composition, often very prone to stress overlap , in general , this will cause abnormal proof floodlight sharp rise more than expected explosion pressure maximum pressure. To this end Unicom hole area should be increased , so that the shape of the pressure inside the enclosure to eliminate duplication . If the actual pressure not eliminate duplication , proof measures should be taken between the chamber and the chamber pressure to eliminate overlap .

2.4 For Ⅱ C flameproof lighting , GB3836.2 strict rules should not be used flameproof gap tends to increase when the plane explosion proof joints , for which China's current flameproof explosion-proof lighting in most cases, Ⅱ C compartment explosion in the form of thread structure to replace the lamp when the lamp lumen maintenance light or physical well open .

LED防爆灯具生产厂家工艺要求,同所有防爆灯具生产一样的原理

浙江柯铭防爆电器有限公司联系热线

浙江柯铭防爆电器有限公司联系热线 扫一扫,手机浏览

扫一扫,手机浏览